|

|

#1

|

|||

|

|||

|

Rewaxing a Flyback

My method..

http://www.youtube.com/watch?v=tVK2ZoiT9uA Same basic transformer as ctc16, most vintage color sets. |

|

#2

|

|||

|

|||

|

this is the coolest video I have seen in a long time.

|

|

#3

|

||||

|

||||

|

You deserve an award for going the extra mile to repair/presere that flyback IMHO.

I still remember you mentioning that idea some time ago on one of the forums and laughing really hard at some ones response of quoting marvin the martian "Where is the kaboom?!! There is suposed to be an earth shattering kaboom!..."

__________________

Tom C. Zenith: The quality stays in EVEN after the name falls off! What I want. --> http://www.videokarma.org/showpost.p...62&postcount=4 |

|

#4

|

||||

|

||||

|

Great job! Is that just plain beeswax? I've been wanting to rig up something for restuffing caps-I need to do some experimenting. After watching your luck at first with that pressure cooker, I didn't think it was going to work. I look forward to seeing how it holds up.

__________________

Bryan |

|

#5

|

|||

|

|||

|

there are a lot of OEM flys that have that kind of cover on them, I suspect they are all going to fail at some point due to excessive moisture (perhaps the real culprit in arcing as opposed to the wire insulation breaking down. After all I presume the main function of all that paper is at least in part for insulation and how good an insulator can it be if its laden with liquid water.

I am really looking forward to the follow on to see if the fly no longer arcs and works as it should. the main point being even OEM flys with this type of cover (the rubber outer cover that is not a potted type material) may have been breach while still in the box if the enviroment it was stored in was high humidity. I know it may sound a bit risky, but perhaps if you have a NOS style fly like this it would be a good idea to go ahead and strip the covering off do this procedure before ever putting it into service. there has been at least one instance where one of these FLYs that looked to be NOS arced over very soon after being put into service. I think in the mean time I will be storing my backup flybacks in a very very dry area, after letting them bake in the attic on a dry summer month like May. Last edited by DaveWM; 11-18-2011 at 11:17 PM. |

| Audiokarma |

|

#6

|

|||

|

|||

|

...

Last edited by andy; 12-05-2021 at 08:19 PM. |

|

#7

|

||||

|

||||

|

I had wondered the same thing. Since wax hasn't stood the test of time, why not use some more modern material? Nobody coats flybacks with wax nowadays.

I once re-coated a flyback with RTV, and in that discussion Eric H. suggested this stuff as a better material, since the thin liquid can seep down into windings: http://www.aervoe.com/paints_coating...y-Coating.html The fly that I did with RTV eventually failed, and I replaced it with a NOS transformer from Moyer's. The new fly was a correct replacement, but it had a plastic raincoat over the winding, rather than wax as on the original. Apparently, even in the few years since manufacturing the original and the replacement, someone had decided that wax was not the best solution:   Just my $0.02. Phil Nelson Last edited by Phil Nelson; 11-19-2011 at 12:35 PM. |

|

#8

|

||||

|

||||

|

I always figured the wax, rubber, or plastic coating was more of a dampening or physical barrier. Surely the wire windings were originally vacuum impregnated with varnish like any other modern transformer? BTW the melted wax will naturally impregnate the windings without a vacuum chamber. Not sure I remember the process, possibly convection from the cooling process.

Last edited by Kevin Kuehn; 11-19-2011 at 12:41 PM. |

|

#9

|

||||

|

||||

|

It was originally thought that wax was impervious to moisture, and it does help, but over time moisture does get through it. Same with old paper caps.

__________________

Reece Perfection is hard to reach with a screwdriver. |

|

#10

|

||||

|

||||

|

But in the 1960's?

|

| Audiokarma |

|

#11

|

||||

|

||||

|

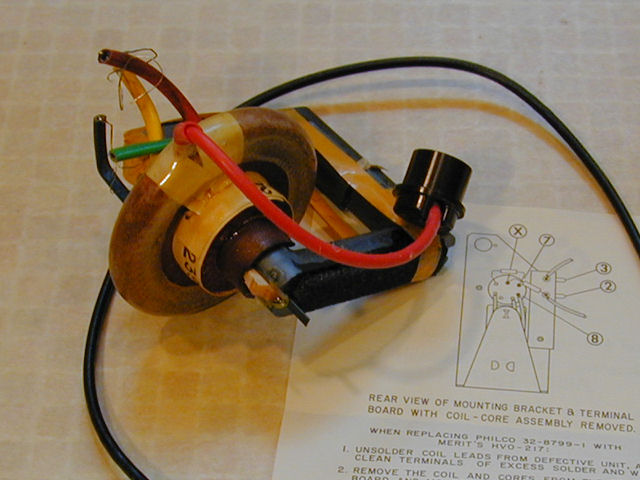

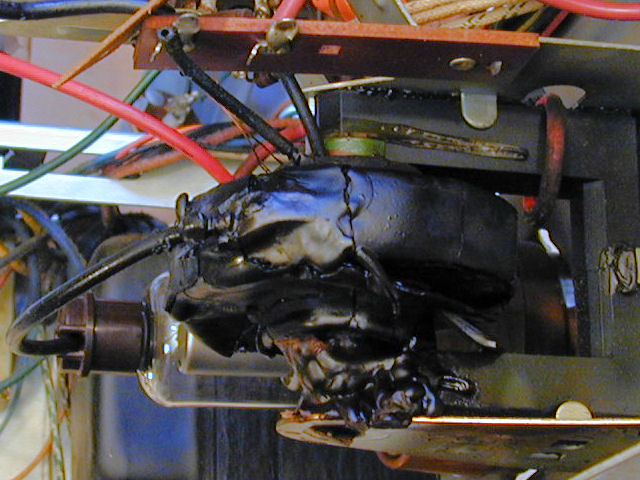

That fly with the melted black wax is from a 1958 Philco. The replacement with the plastic cover was presumably a few years newer.

TVs were appliances. Within their expected service life (who knows -- 10 years or less, on average?), wax must have worked fairly well, or manufacturers would have been driven to find a better solution much earlier. I think it was mentioned in the video that the heat of regular operation probably kept things drier during a TV's "first life." The original designers probably didn't plan for a "second life," during which it would sit unused in a damp basement or garage for decades. Regards, Phil Nelson |

|

#12

|

||||

|

||||

|

You guys are probably right. I just assumed that the coatings were originally chosen more for their HV insulating or harmonic dampening properties rather than a moisture barrier. I've read that if the flyback donut becomes loose on the core, that you can get some nasty ringing in the horizontal. Wax would be very good at dampening out mechanical vibrations at the horizontal frequency, as would any soft pliable material.

|

|

#13

|

||||

|

||||

|

Usually they used microcrystalline wax - it's non-hygroscopic (won't absorb/pass water). We used it in the Navy to coat fiber shields around 40KV Airborne Radar power supply units. It will support fungal growth, but a single drop of mineral oil in the molten wax stops that. We simply brushed it on with a natural bristle brush, and used a solder pot. Never had a problem with it cracking or arcing.

Here's one source of wax: http://www.freemansupply.com/MicroCrystallineWa.htm I've got ZERO experience in buying wax, 'cept for my wife's candle making. Cheers,

__________________

Brian USN RET (Avionics / Cal) CET- Consumer Repair and Avionics ('88) "Capacitor Cosmetologist since '79" When fuses go to work, they quit! |

|

#14

|

||||

|

||||

|

Quote:

I've yet to see any coating except RTV3145 stick to a flyback saturated with wax. Conrac RGB monitors in Grumman Aerospace used a clear, solid plastic donut clamped around the flyback secondary, probably for moisture proofing or corona prevention. Later models used a potted approach, much like GE started doing with the MA/MB color chassis flybacks. They used a solid plastic shell, with the primary and secondary laid in some funky green potting material. Philco/Sylvania flybacks in the 80's used a similar approach. Cheers,

__________________

Brian USN RET (Avionics / Cal) CET- Consumer Repair and Avionics ('88) "Capacitor Cosmetologist since '79" When fuses go to work, they quit! |

|

|

|