|

|

|

|

#1

|

||||

|

||||

|

If the repair was successful it may have as much as decades more time left on the fly, assuming temp and current can be kept under control.

Part of me wonders if the copper corrosion is natural. I know this example is a good 30 years older, but I've done ~3-4 Philco 60 chassis cathedral radios (2 more waiting in the wings) and 2-3 of their loss leader cousins the 80 chassis (2 of those waiting my bench also), and all but one of them (a 60 chassis) had either the antenna transformer, osc transformer or both with corroded open windings (and these windings have a coating besides the wire lacquer sealing?/holding them to the forms)...Only one had the problem in the lead-in, the rest were mid winding...Sometimes with multiple opens. The first ones I fixed in a similar fashion to what your tech did, the rest especially the ones with multiple opens I just rewound the ~<20 turns with phono pickup wire. All these sets were ones with good original cabinets, not barn dwellers, yet still were like that.

__________________

Tom C. Zenith: The quality stays in EVEN after the name falls off! What I want. --> http://www.videokarma.org/showpost.p...62&postcount=4 |

|

#2

|

||||

|

||||

|

Quote:

When I asked Mike why RCA would engineer a flyback with no ventilation, I said was this a money grab to get repair tech's to the home, he said, "well the fly backs were readily available but possibly to minamize arcing."

__________________

|

|

#3

|

||||

|

||||

|

It is my opinion that copper wire corrosion in the HV cage is not uncommon. I had this problem on my Hallicrafter 820 set. I think this is exacerbated inside the HV cage due to corona that can cause ozone, which is highly corrosive. A small knick in the varnish covering the wire can expose bare copper which will oxidize over time and physically weaken the wire.

__________________

Vacuum tubes are used in Wisconsin to help heat your house. New Web Site under developement ME http://AntiqueTvGuy.com |

|

#4

|

||||

|

||||

|

Quote:

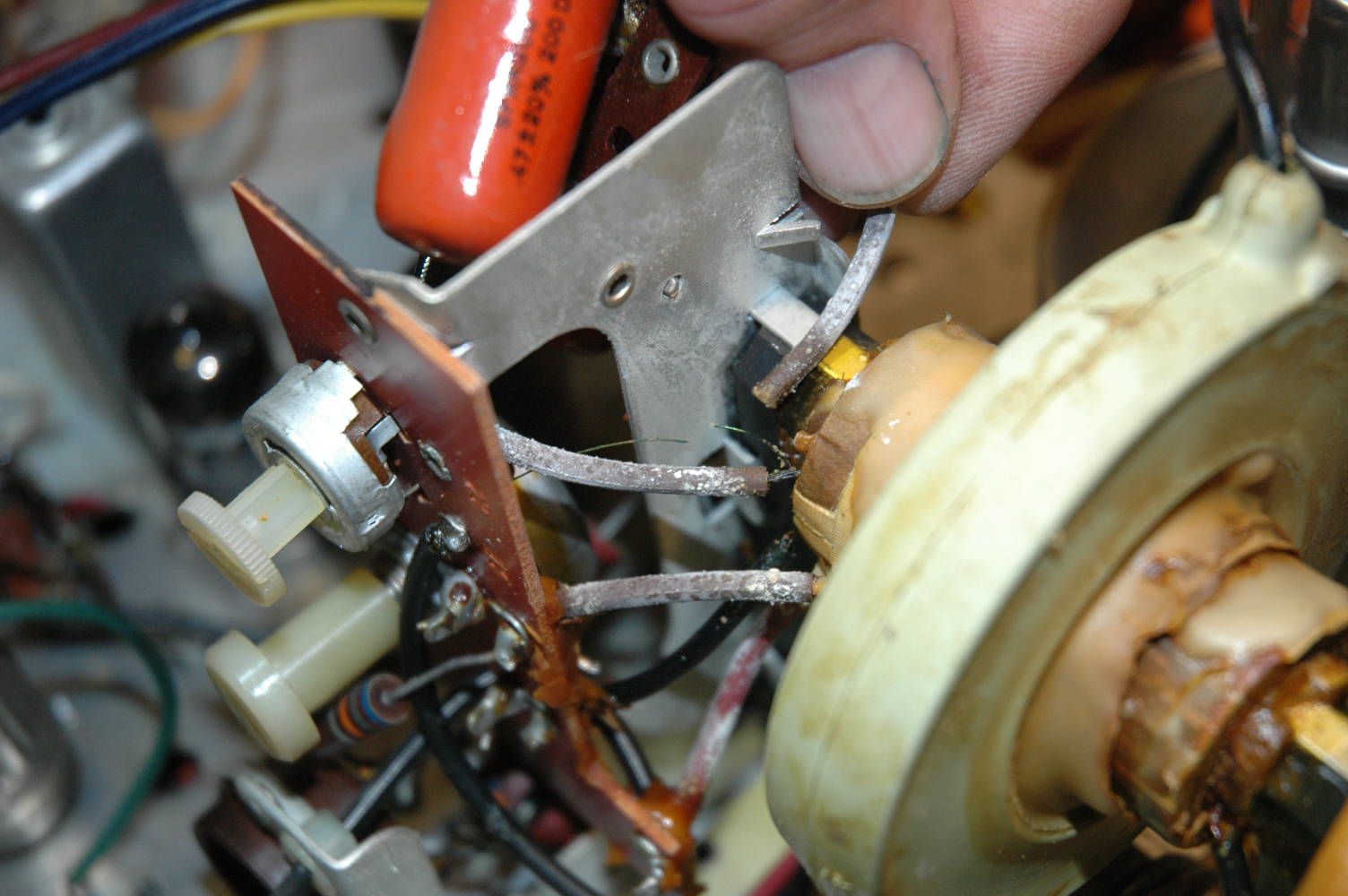

After repair.

__________________

|

|

#5

|

||||

|

||||

|

Nice, but I would j hook the copper wire to make the connection long term stable. In your case it could be better not to touch the connection any more to avoid further damage. I usually clean flybacks (from our european b&w sets) with WD40 to protect them from moisture and soften dried out isolations. Take care if there are carbon track pots and don't use WD40 in this case.

|

| Audiokarma |

|

#6

|

||||

|

||||

|

Quote:

|

|

#7

|

||||

|

||||

|

Quote:

Wet WD40 isnt that easy to light either. Many years ago I was trying to fix a 30s fan that I eventually found had a bad contact brush and it was arcing like crazy but not easy to keep enough WD40 on the rotor to sustain burn for more than a couple seconds.

__________________

Tom C. Zenith: The quality stays in EVEN after the name falls off! What I want. --> http://www.videokarma.org/showpost.p...62&postcount=4 |

|

|

|